2020-12-10

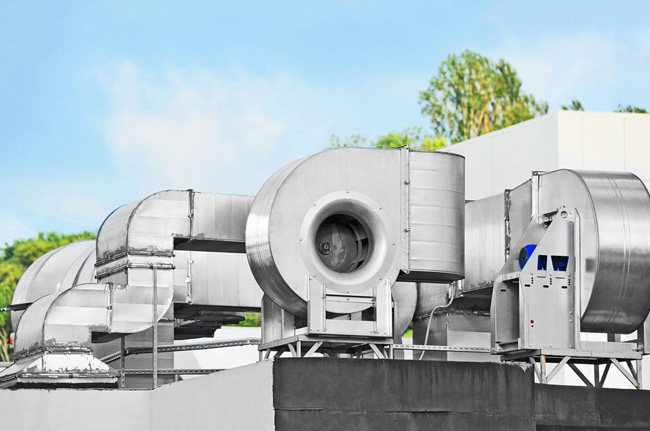

Commercial fans are widely used, but the operation condition is bad, bearing requires higher speed, up to 3600 rpm. The operating environment of the fan is dusty, and the exposed bearing is vulnerable to dust. Noise affects human health, leading to customer complaints, requiring bearings to operate under low noise for a long time. It is required to select correct grease and proper amount of grease pre filling. The fan is often in continuous operation, so the outer spherical bearing is required to be in the best rotation state at all times. Due to long-term operation, low temperature rise is required, otherwise the bearing will fail prematurely. As the core parts of the fan, the bearing is installed in all parts of the building, and the maintenance cost is high.

According to the working condition of high speed, the internal structure of F series bearing is optimized and adjusted to adapt to the condition of high speed, which can still maintain long life and lower noise level. According to the working condition of the fan, the special seal ring for the fan bearing is developed, which has the characteristics of light torque, high dust-proof and not easy to loosen, and has obtained the patent copyright. High quality motor grease and optimized lubrication channel ensure continuous operation of bearings under lower noise level for a long time, reduce downtime and maintenance cost. The stable tolerance fit between F series bearing core and bearing seat ensures the smooth operation of bearing under eccentric working condition. The accurate material control of the bearing seat ensures that the bearing can still maintain excellent running performance under vibration conditions. Special anti loosing jacking wire is used for bearing with jacking wire and eccentric sleeve.